2021 CIMT | Burst ! See 7 * 24 hour uninterrupted flexible machining job

CIMT2021 (17th China International Machine Tool Exhibition) will be inaugurated at Beijing China International Exhibition Center (New Pavilion) from April 12 to 17, 2012.

As one of the four major international machine tool exhibitions, China is the most well-known, largest and influential professional machine tool exhibition, as well as European EMO, American IMTS and Japanese JIMTOF.

WELLLIH ROBOTS (Weili Robot), booth No. E1-B211, invites you to come to the exhibition site to exchange the very forward-looking intelligent turnkey solution.

WELLLIH ROBOTS will provide a complete solution for flexible manufacturing of multiple varieties and small batches.

You will see 7*24 hours of uninterrupted flexible machining operations, more economical rigid automation and intelligent production line complement each other to achieve efficient flexible intelligent manufacturing.

FMS Flexible Manufacturing System

It is a hardware-based manufacturing solution mainly for small and medium-sized batches, multiple varieties and continuous production.

With the support of software, the flexible scheduling of machining plan can be realized by operating software.

FMS system is composed of processing system, material storage and transportation system, control and management system, which can greatly improve the utilization of equipment.

Increase productivity, stabilize product quality, reduce production costs, and improve market responsiveness.

At the same time, it can improve the production schedule, order management and scheduling, material, logistics and warehousing, tool management, etc., and has the advantage of continuous and unattended flexible machining operation.

Strong cooperation with SOFLEX, a leading supplier of flexible manufacturing systems in the field of metal machining, helps users achieve efficient and flexible production with super-high quality performance.

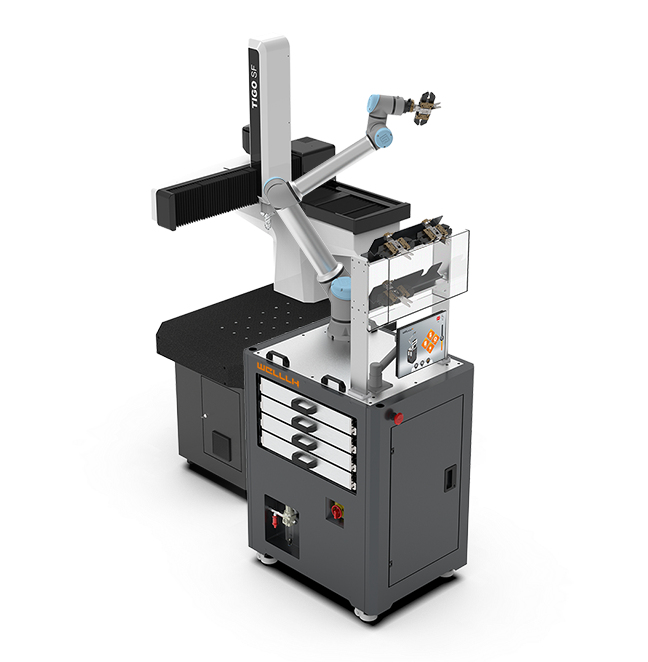

3S-LFlexible intelligent measuring workstation

The CNC system of cooperative robot and CNC machine tool is opened and integrated by using self-developed control system.

It is an organic combination of production planning (management) and automation (execution), with ultra-high collaboration and safety.

It is equipped with drawer-type loading system, which can transfer quickly to another CNC machine tool and realize fast link with machine tool communication.

Through guided task setting, continuous automation can be achieved by simple operation of software.

Tightly cooperating with the world's leading metrology and manufacturing program expert, Haxcon, a compact design, one-stop inspection,

It realizes the functions of automatic feeding and unloading, automatic measurement, automatic sorting, measurement data storage and management of various workpieces.

To achieve cost reduction, efficiency improvement and product quality for customers regardless of batch size.

In addition, heavy-duty gantry trusses will be brought with a maximum load of 2T.

Experience the extra-high rigidity, extra-heavy load, ultra-high accuracy and other performance characteristics it brings, and it is widely used in heavy load handling.

Heavy Duty Gantry Truss-1T

In addition, the highlight is WELLLIH ROBOTS informatization subsidiary Weilian Information.

It will allow you to fully appreciate the infinite possibilities of intelligent manufacturing, the new generation of intelligent manufacturing equipment and technology that is deeply integrated with the latest information technology.

To achieve a new intelligent manufacturing mode with a deep integration of two types for customers, improve management, improve efficiency and work together with global users to improve and grow.

In the meantime, you can also have static access to WELLLIH ROBOTS'flexible intelligent production solutions and stand-alone automated production tools for machine replacement at the following partner booths.